Our Services

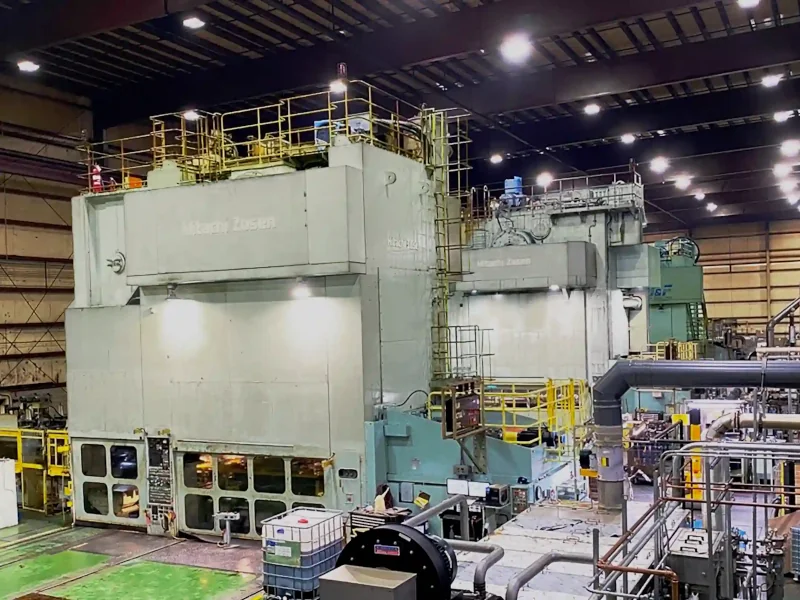

With two strategically located facilities—Cardington, Ohio (595,000 sq. ft.) and Cullman, Alabama (280,000 sq. ft.)—we deliver high-volume manufacturing with exceptional precision and efficiency.

As part of the North American Yutaka Group (NAYG), our capabilities include advanced pipe bending, welding, and stamping for exhaust systems (hot- and cold-end) and electric vehicle (EV) motor components.

Supported by onsite North American Regional Operations (NARO) in Cardington, we combine technical expertise, leading-edge technology, and responsive service to meet the evolving demands of the automotive industry.

If you would like more information please download the brochure below.

Stamping

Our facility houses presses, including large progressive and high-volume units, handling 0.8–10 mm materials and deep draw stamping. We streamline production by integrating value-added components in-house for better fit, function, and cost control.

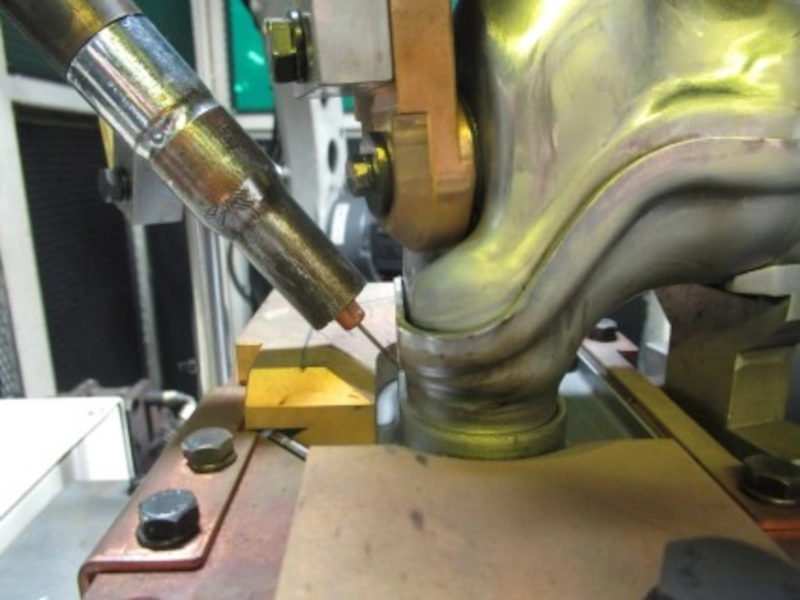

Precision Welding

Since 1996, we’ve specialized in MIG, TIG, and laser welding, with over 30% of products using all three to meet performance and dimensional standards.

With 127+ advanced tech robots, we handle everything from small parts to components up to 4.1m long and 2m wide.

From high-precision laser welds to high/low volume TIG, our flexible capabilities support diverse product designs and requirements.

Pipe Bending

At CYT-OH & AL, we bend complex pipe designs from 38.1mm to 70mm in diameter, supporting both high- and low-volume production with precision and value.

With 10 CNC benders integrated with robots, we process pipes up to 2.1m long while ensuring optimal fit and finish.

Research, Development, & Support Services

At CYT, research and development is more than just a department—it’s the driving force behind our innovation. Our R&D team works closely with customers to bring product ideas to life, from early concept sketches all the way to full production. Whether it’s an exhaust system, a torque converter, or an EV component, we make sure every part meets high performance and quality expectations